Measuring vehicle SKM

Our SKM skid resistance measurement systems are mainly used for network-wide condition monitoring. The range extends from the district road network to motorway inspection. Other applications include functional tests as part of PPP contracts or object-related skid resistance recording as part of the acceptance of new construction or maintenance measures and for checking accident blackspots.

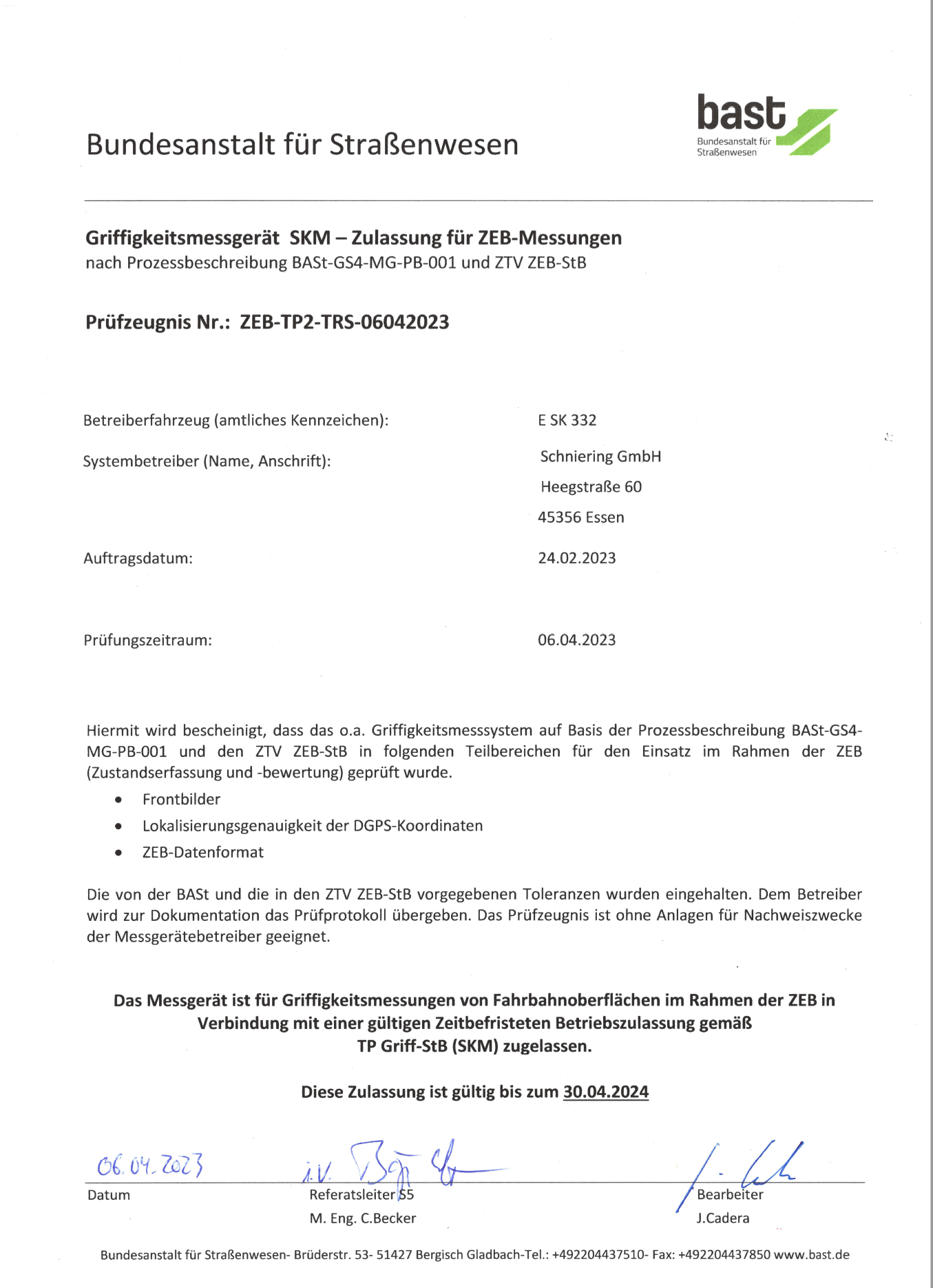

Our SKM measuring systems are tested annually by the

German Federal Highway Research Institute (BASt).

The SKM measuring system has the following sub-systems for condition monitoring:

- Measuring unit for the detection of skid resistance according to the sideway force measuring method in accordance with TP Griff-StB (SKM)

- High-resolution front camera with special aperture control for fast-moving recording of videos or individual images of the road space (route images)

- Highly clocked laser sensors for recording the macrotexture in the right-hand rolling lane of the vehicle

- System for detecting the lateral distance

Water, surface and air temperature recording system - Pumpless control system for applying a defined water film in front of the measuring tyres

The measuring system can be used at speeds of up to 80 km/h. Due to the installed safety devices according to DIN 30 710 and HSM 2000, the vehicle is intrinsically safe. The measuring speeds are defined for the different road categories (40, 60 and 80 km/h), so that traffic obstructions caused by “swimming along” in the traffic are avoided as far as possible.

The skid resistance measured objectively by the SKM measuring system is an essential basis for the following:

- the provision of network-wide condition information as objective baseline information for short-, medium- and long-term conservation decisions.

- the optimised use of increasingly limited resources

- transparent decisions within building administrations as well as in external presentation

- Control over the effect of measures and the effect of their delays

- the forecast of the future network condition

- the practical findings on the success/failure of types of measures and building material concepts in conservation

In order to enable the true-to-position mapping of the captured data and images onto the digitised road network, a position detection by means of a DGPS system (Differential Global Positioning System) is integrated into each measuring system. Coupled with distance measurement via a rotary encoder, standard accuracies of typically ± 3m are achieved.

The recorded measurement data are evaluated and assessed according to the order-specific specifications and taking into account individual concerns, usually on the basis of regulations such as ZTV ZEB-StB , the VSS standards or also METHODE D’ESSAI LPC, and are usually handed over to the client in the following formats:

- Raw geodata / raw raster data according to the format definition of the Federal German Highway Research Institute (BASt)

- Map-Info relation

- shape-file

- Visualised in STRADIVARI®

- Result file on CSV, Excel or dBase basis

- State maps / strip maps / raw data strip maps in digital and printed form

The corresponding image data is transferred to an image database in the specified storage system on data media.